Types of Time Recorders

There have been several different methods invented and employed to achieve the same objective – to accurately record the number of hours worked by each employee, save the employer money, and make money for the inventor. To be successful, the machines had to be accurate, reliable, fool-proof, and easy for workers and time clerks to operate.

Below are brief descriptions and examples of the various methods used. More detailed descriptions and drawings of each type as described and drawn by the inventors themselves can be found on the Patents page.

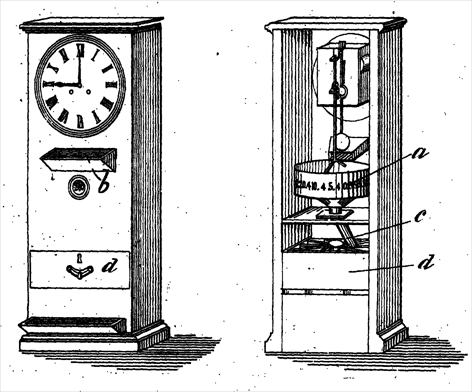

Time Check Machines

These were the first type of time recorders used in the UK, notably patented and manufactured by William Llewellin (1881) and Frank Brook (1893). Seemingly first invented by John Adams in the UK in 1855, there were many patents filed for this type of machine in the UK and USA in the second half of the 19th century.

The basic form utilised a large, vertically-mounted segmented drum, rotated by a heavy-duty clock movement. Each section of the drum represented a time period, for example from 7.00 am to 7.30 am. Each worker would have his own numbered metal ‘check’ or token, stored in an adjacent cabinet or rack. On arrival at work, each worker would select his check and insert it into the machine in a slot or hole positioned above the drum.

An internal chute would then send the check to the segment of drum representing the time period of arrival. Once all the workers had arrived (say by mid-morning) the time clerk would remove or access the drum, log the arrival time of each numbered check, and replace the checks into the cabinet for the same procedure to take place when the working day was over.

Several methods were developed to record the arrival and departure time of each worker automatically and more accurately. These included procedures such as using 2 checks each day for each worker clocking in and out, or ink ribbons and time-graphed paper under the drum which were marked by the force of each dropped cylindrical check embossed with its number, and employing striking mechanisms to stamp or punch card or paper with the deposited check’s identity number.

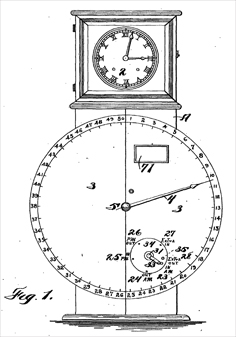

Dial Recorders

Invented by Alexander Dey in Glasgow in 1888, dial (or radial) machines used a large dial with equally-spaced, sequentially-numbered holes. The end pointer on a centrally-pivoted arm was inserted by each worker into their corresponding numbered hole, which moved the position of a central paper drum to print the date and time of entry and exit of each number on a pre-printed paper roll inside the housing. The time-stamping mechanism was driven by an 8-day movement, with another mechanism to set the day of the week and period (morning or evening). The information from the printed paper roll would be used by the wages clerk to calculate each employee’s pay at the end of the week.

The machines varied in size, dependent on the number of employees that were required to use them. This was usually between 50 and 200 workers. The more numbers, the larger the dial, the larger the printing drum, and the larger the machine.

This design was used for several decades, with modified versions manufactured and sold by other time recorder companies.

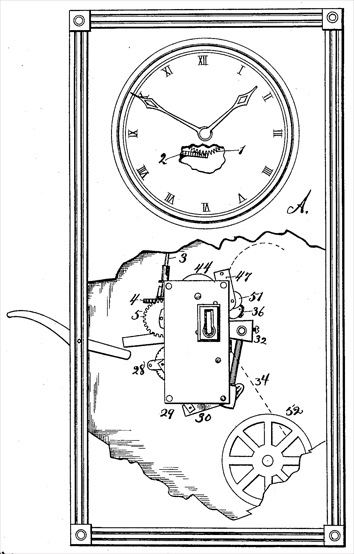

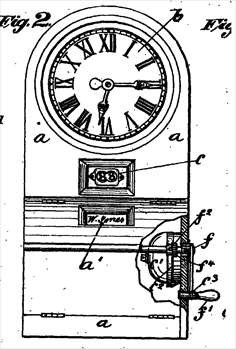

Key Recorders

Invented by Willard L. Bundy in the USA in 1878, this type of machine recorded the arrival and departure times of workers on a roll of paper by the insertion and rotation of a key, each key individually numbered 00-99 for each employee. The clocking-in mechanism, driven by a heavy-duty 8-day movement, used an ink ribbon to accurately stamp an imprint of the key number along with the date and time in hours and minutes.

A numbered key rack would be situated adjacent to each clock. A time clerk would be employed to remove the stamped section of the paper roll at the end of the day or week, to record the attendance times of each worker and calculate the payroll accordingly.

Many modifications and improvements were made over the several decades this successful machine was used, and the underlying design principle was used by many of the other major time recorder companies.

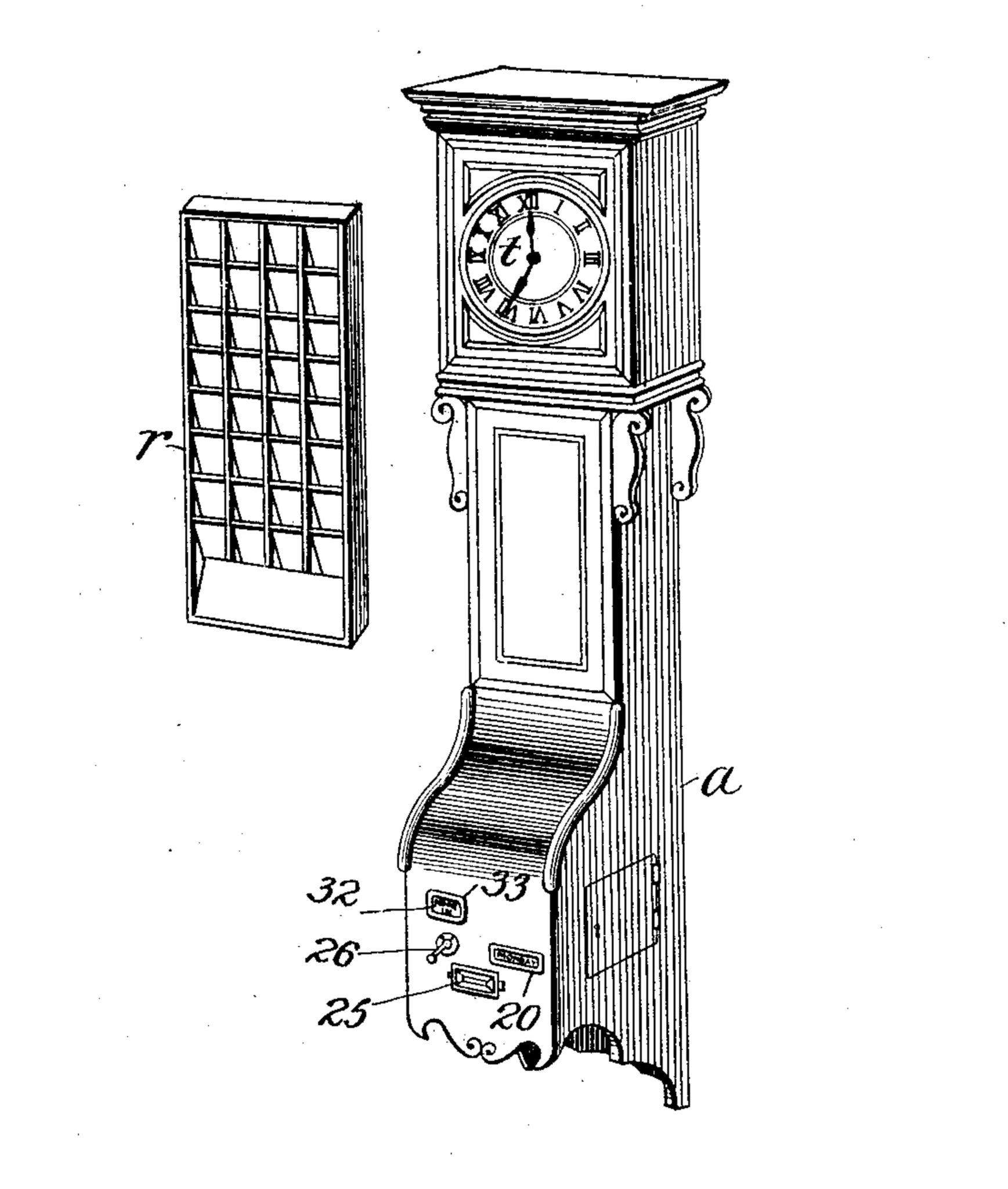

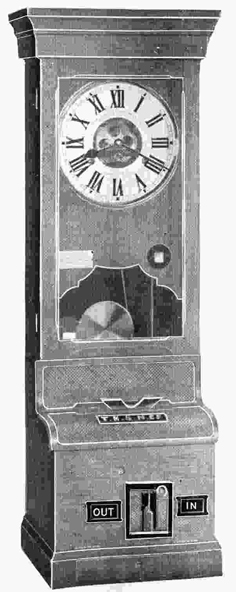

Card Recorders

Daniel M. Cooper is credited for inventing the first card recorder, the Rochester, in the USA in 1894. By far the most widely used and successful type of time recorder, the same basic design remained in use for nearly a century. The design did not limit the number of employees that it could accommodate, with each worker having their own clocking-in card stamped on a weekly basis to record their arrival and departure times each day by date, hour, and minute.

The cards were stored in numbered racks adjacent to the machines. With no paper roll to extract and change, the wages clerks would calculate the pay for employees from the information printed on each card at the end of each week.

The major time recorder manufacturers all had their own versions of card recorders, with many variations and improvements over time, though less ornate as the 20th century progressed and production costs became a greater limitation in industry. All time recorder mechanisms were driven by substantial 8-day movements, with some manufacturers such as Gledhill-Brook using very accurate fusee movements.

Card Clip Recorders

Card-clip time recorders worked on the same principle as card recorders, but each time the card was stamped, a notch was clipped out of it. This ensured that the card would be positioned one line up the next time the card was inserted. The machines had removable trays under the clipping mechanism to catch the card clippings, which would need to be emptied periodically.

The most notable examples of this type of machine are the National Time Recorder ‘Clipit’ and Gledhill-Brook’s ‘Clipper’ models, both of which were introduced around 1920.

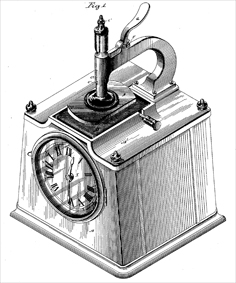

Autograph Recorders

The earliest autograph (or signature) recorder appears to have been invented in Chicago in 1888, and manufactured by the Chicago Time Register Company. The basic principle involves a mechanism driven by a clock movement, which prints the date and time of entry and exit alongside a written signature.

The signature is written on the paper through an aperture while a lever is pressed by a worker to advance the paper roll for the next user. This was usually very awkward for left-handed employees! The wages clerk would remove the printed portion of the paper roll at the end of each week to calculate the wages due to each employee.

Autograph recorders were generally desktop machines with many ‘portable’ versions, designed more for office workers rather than factory floor workers (presumably, under the assumption that not all manual labourers could write their name). Leading manufacturers produced different versions of autograph recorders, varying in styles and size, from wall-mounted to portable desktop types.

Time Stamps

Time stamps were basic but effective small desktop machines that incorporated a clock movement and mechanism to print the date and time on a card or paper, when inserted by the employee and a lever pressed.

Many versions of this machine were patented by the end of the 19th century in the USA, with the most successful manufacturers being The Accurate Time Stamp Company (1890), which later became The Standard Time Company (acquired by Bundy in 1899), and The Follett Time Recorder Company (1907), which still exists today. Blick marketed the Follett time stamp in the UK from 1917, and later marketed a version made by the National Time Recorder Company in the 1920s.

Job Timers

Job timer (also known as job cost or time cost) machines were essentially glorified time stamps which varied in size between different manufacturers, from portable desktops to full-size wall-mounted versions. Operation was simple, by card insertion and a lever press to stamp the date and time.

They were sold as machines that could accommodate any type and size of card, primarily for casual workers or workers on long, unusual, or temporary shifts. More complex machines were designed and supplied with specific cards that would generate a weekly worker attendance record, such as Gledhill-Brook’s ‘Universal’ recorder.

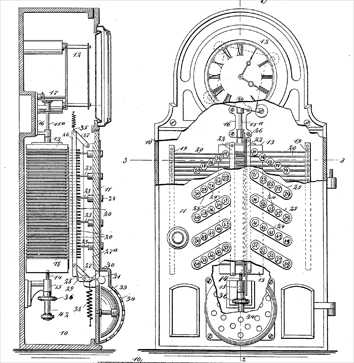

Button Press Recorders

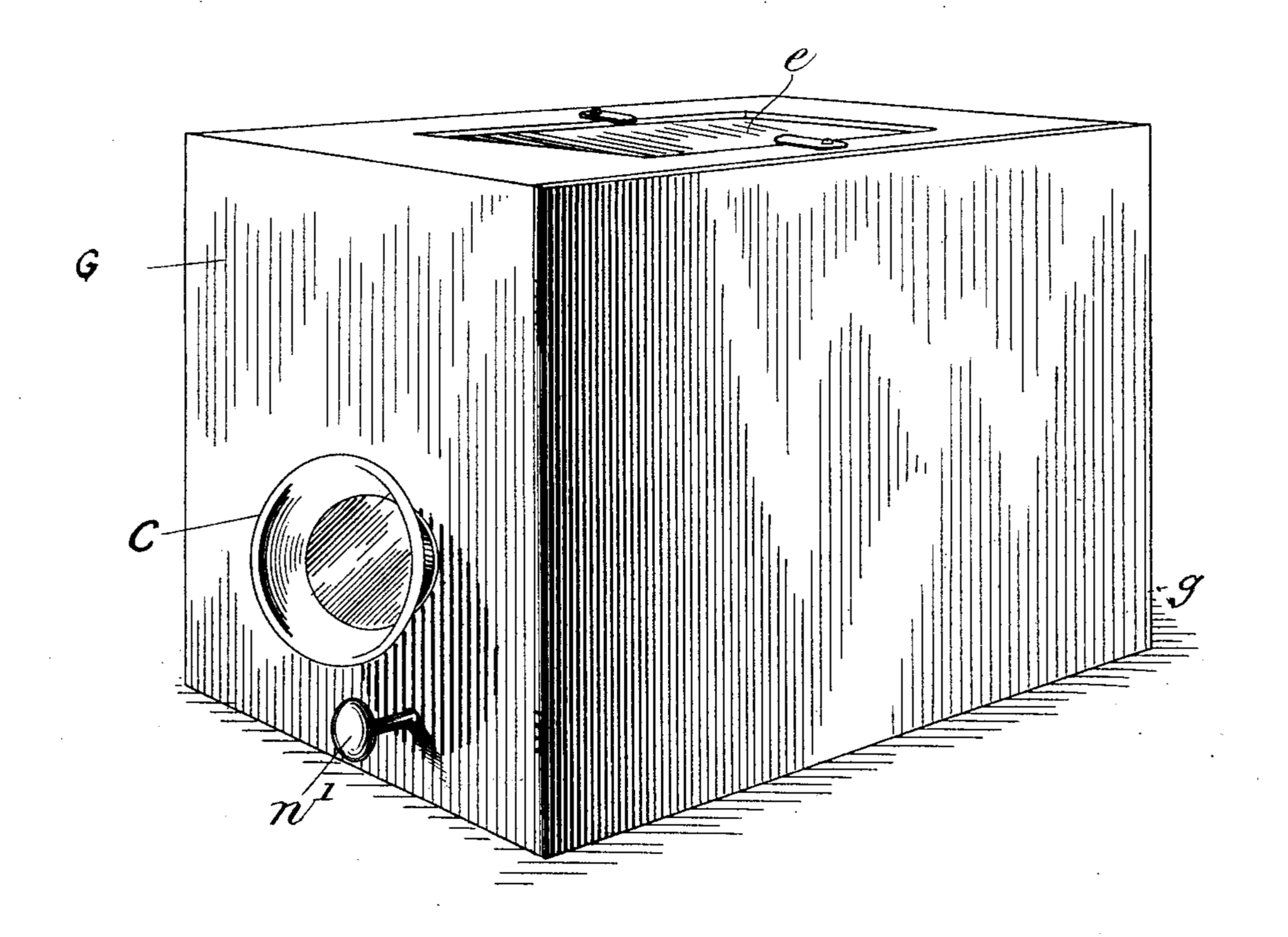

The example pictured, a sketch taken from his 1893 patent, was an early design by Edward G. Watkins. The invention of this recorder resulted in him founding the Simplex Time Recorder Company in 1894.

To operate these recorders, workers simply pressed their allocated number on the front of the machine upon starting and leaving work. This action punched a hole in pre-printed paper marked by time and worker number. The paper was held on a large drum, which was rotated by an 8-day clock movement. A full description and more illustrations by the inventor can be found on the Patents page.

The button press didn’t become a popular method, probably due to limitations in the number of workers it accommodated, the large paper roll required, and the necessity to accurately set the paper on the drum.

Photographic Recorders

I came across this invention while trawling through hundreds of patents. I don’t suppose it ever reached the production stage, but it must be one of the most unique and innovative designs of its time (London, 1898).

The concept was a combination of a clock, printing mechanism, and camera, which were used to stamp the date and time onto a photograph of the employee’s face when starting and leaving work. It would no doubt have been difficult to maintain with the camera technology at the time! If only webcams had been around…

A full description of the photographic recorder and more illustrations by the inventor can be found on the Patents page.